Precision, Innovation & Quality Since 1978

X-Plor Custom Plastics Inc

Reliable, flexible, and precise plastic injection molding for companies that need consistent, long-term production support

At X-Plor Custom Plastics we specialize in running customer-owned molds with dependable quality and efficiency. Located in Cedar City, Utah, we operate nine injection molding machines ranging from 25 tons to 400 tons, supporting short and large production runs across multiple industries.

More than 4 decades of experience

In operation since 1978

Injection Molding

Injection Moldines Machines with presses from 25 to 400 tons.

Flexible Production Runs

Short-run and high-volume capabilities.

Material Expertise

Acrylic, Nylon, ABS, Polycarbonate, Polypropylene, and more.

About Us

X-Plor Custom Plastics

Founded in 1978 in Santa Fe Springs, California, X-Plor Custom Plastics, Inc. began when founder John and two partners tired of seeing better ideas ignored in the plastic pipe fittings industry decided to create a company where innovation and craftsmanship mattered.

By 1985, John became the sole owner. In 1992, X-Plor relocated to Cedar City, Utah, becoming the first plastic injection molding plant in the region. Since then, the company has continued to operate as a small, dedicated team focused on reliable production, hands-on quality control, and long-term customer partnerships.

Today, X-Plor runs a wide range of industries with practical, dependable service.

SERVICES & CAPABILITIES

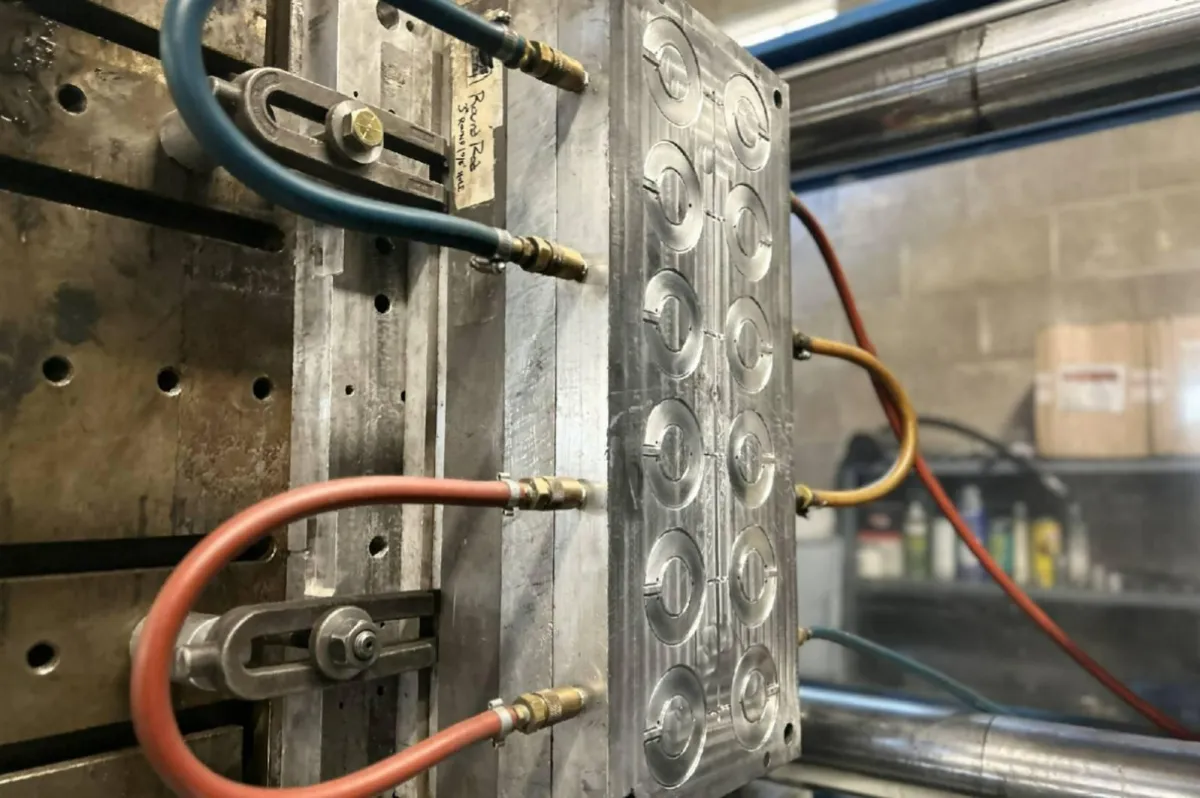

We focus on delivering consistent molded parts through reliable operations, proper tooling care, and flexible production capabilities.

Custom Plastic Injection Molding

We specialize in running and maintaining customer-supplied molds. Our team sets up, operates, and monitors tooling to ensure consistent, repeatable quality across small and large parts.

Short & Large Production Runs

We support everything from prototype quantities and short runs to sustained, high-volume production. Our flexibility allows customers to scale without the need to switch facilities.

Materials We Work With

We mold a broad selection of materials, including:

Acrylic - Nylon - ABS - Polycarbonate - Polypropylene.

We can run customer-provided materials or help evaluate workable alternatives.

Mold Setup, Maintenance & Care

Mold maintenance and cleaning

Troubleshooting part or tooling issues

Ensuring molds run smoothly and consistently

Extending tooling life through proper care

Assembly & Quality Checks

Light assembly

Part inspection

Packaging support

Logistics coordination with your process

Process & Equipment

Hot water circulation systems

Mold heaters

Hot air dryers

Desiccant dryers